MSD Spark Plug Wires – Construction, Custom Assembly, and Applications from Mopeds to Top Fuel Racing

by Jari H., 24.1.2026

In an ignition system, the spark plug wire is often the component that receives the least attention. In reality, it is the final and most critical link in the chain: if the spark does not reach the plug in a controlled and interference-free manner, fine-tuning the ignition box, coil, or timing maps will not make a difference.

MSD spark plug wires are designed as part of a complete system – especially for applications where reliability, high engine speed, and interference-free operation are required.

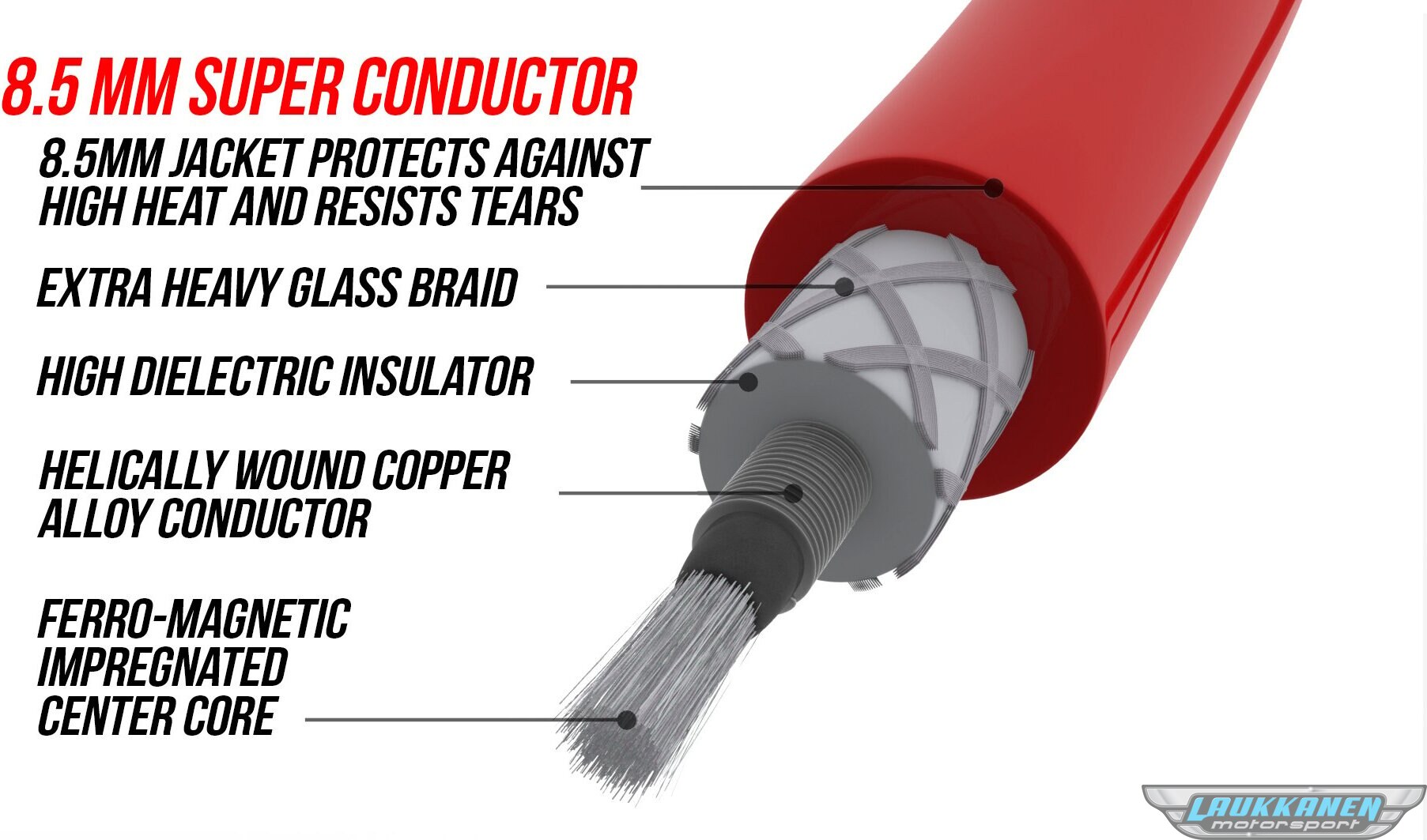

MSD 8.5 mm Super Conductor – what the wire is really made of

The MSD 8.5 mm Super Conductor wire is not based on a traditional carbon-core conductor. Instead, it uses a ferromagnetic core wrapped with a copper alloy winding. This design allows extremely low resistance without allowing electromagnetic interference to become an issue.

The construction includes:

- ferromagnetic core (approximately 40–50 ohms per foot)

- helically wound copper alloy conductor

- high dielectric strength insulation

- heavy fiberglass reinforcement

- 8.5 mm silicone outer jacket

The result is a wire that transfers spark energy efficiently while still suppressing EMI and RFI through its structure – without relying on high resistance values.

More information about MSD spark plug wires can be found on the manufacturer’s website.

Heat resistance – what the wires and boots can really handle

The silicone jacket of the MSD 8.5 mm Super Conductor wire is designed to withstand continuous temperatures of approximately 280–300 °C (≈ 550–570 °F).

Spark plug boots typically withstand around 300–315 °C (≈ 600 °F).

In practice, this is sufficient for most applications, including:

- street cars

- performance and hobby vehicles

- motorcycles

- normal track use

- marine applications

If the wire or boot runs close to exhaust headers, downpipes, or turbochargers, or if the application involves:

- endurance-style use

- extended wide-open-throttle operation

- high-heat, boosted engines

Additional heat protection is strongly recommended.

Heat sleeves and protective boots significantly reduce radiant heat and extend the service life of both the wire and the boot. This is not just a precaution, but effectively a requirement in more demanding applications.

Why build MSD spark plug wires yourself from bulk components

Pre-assembled spark plug wire sets are often a compromise:

- wire lengths are not ideal

- routing places wires too close to heat sources

- engine modifications break factory fitment

Custom-built spark plug wires from bulk components solve these issues in one step.

Advantages of the bulk approach:

- wires are made to the exact required length

- routing can be planned properly

- appearance and functionality go hand in hand

Spark plug wire components:

Dielectric grease – a small detail with a big impact

Dielectric grease should be part of every proper spark plug wire installation. It is used:

- inside the spark plug boot

- on distributor, coil, or ignition box terminals

Benefits:

- prevents moisture from entering the connection

- reduces corona discharge

- makes future wire removal easier

- improves long-term reliability

This is not about theoretical performance, but about ensuring the system continues to work reliably years down the line.

Tools – what you need and what you don’t

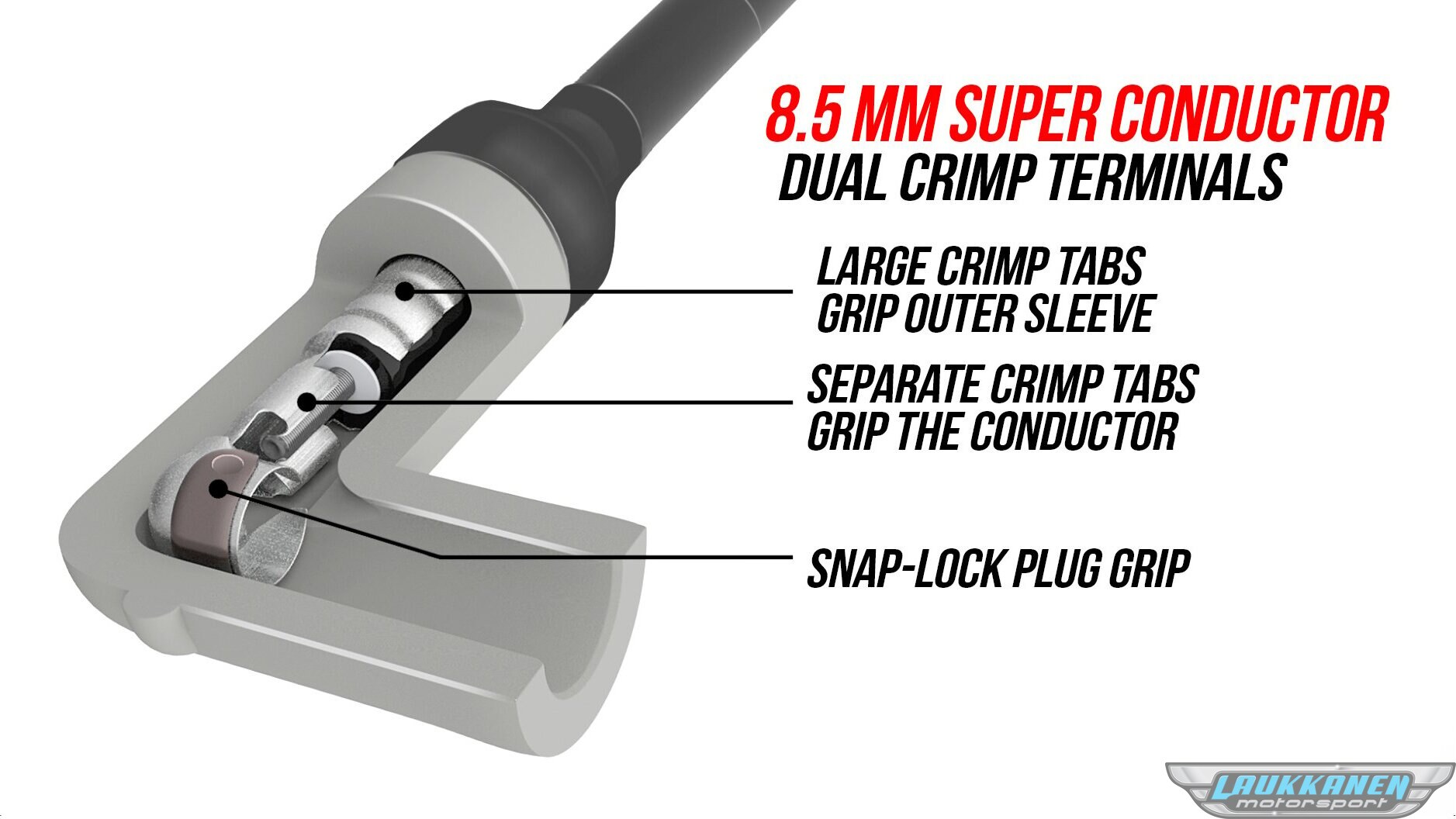

MSD 3503 – a sensible and effective basic solution

The MSD 3503 crimping tool is sufficient for most users.

With it, you can:

- crimp the terminal onto the outer jacket

- ensure solid mechanical retention on 8.5 mm wire

Folding the conductor core can easily be done with standard pliers. This combination is cost-effective and fully functional.

MSD 35051 – professional-grade combination crimper

The MSD 35051 is a versatile tool that allows you to:

- strip the wire

- crimp both the core and the jacket with the same tool

This tool is clearly more expensive, but in return:

- work is faster

- results are consistent and repeatable

- interchangeable jaws and dies can be used on the same frame

Available options include:

- Abico jaws

- Weathertight terminal jaws

- Deutsch terminal jaws

This is a sensible choice if you build spark plug wires frequently or do a lot of electrical work.

Pre-assembled MSD spark plug wire sets – when you want a fast and reliable solution

Not every project requires or justifies building spark plug wires from scratch. In these cases, pre-assembled MSD spark plug wire sets offer a quick and dependable alternative.

Pre-assembled sets offer:

- MSD 8.5 mm Super Conductor construction

- factory-crimped, properly assembled terminals

- reliable performance without additional setup

- fast installation, especially for common engine configurations

Pre-assembled sets are well suited for example to:

- street cars

- stock or lightly modified engines

- applications where wire length and routing do not require customization

If the engine bay has unusual routing, forced induction, tight exhaust packaging, or if a perfectly tailored installation is desired, custom-built wires from bulk components are often the better solution. As a baseline option, however, pre-assembled MSD sets are practical and reliable.

Applications – a genuinely wide range

The MSD 8.5 mm Super Conductor wire works in virtually all ignition systems where a reliable spark is required:

- mopeds and motorcycles

- carbureted engines

- direct ignition systems

- CDI systems

- MSD and other ignition control boxes

- magnetos (e.g. Mallory SuperMag, MSD ProMag 12 / 20 / 44)

- road racing, drifting, and endurance use

- drag racing and Top Fuel–level competition

Thanks to the wire’s construction, separate resistor boots or additional noise suppression components are usually not required, as interference suppression is handled within the wire itself rather than by increasing resistance.

An MSD spark plug wire is not just a conductor, but a functional part of a complete ignition system. When wires are built from high-quality bulk components and installed correctly, the result is:

- strong and consistent spark energy

- interference-free operation

- excellent heat resistance

- long service life

With the right components, proper heat protection, dielectric grease, and sensible tools, building spark plug wires is straightforward – and the end result is built to withstand real-world use.

+

+