Understanding U-Joints

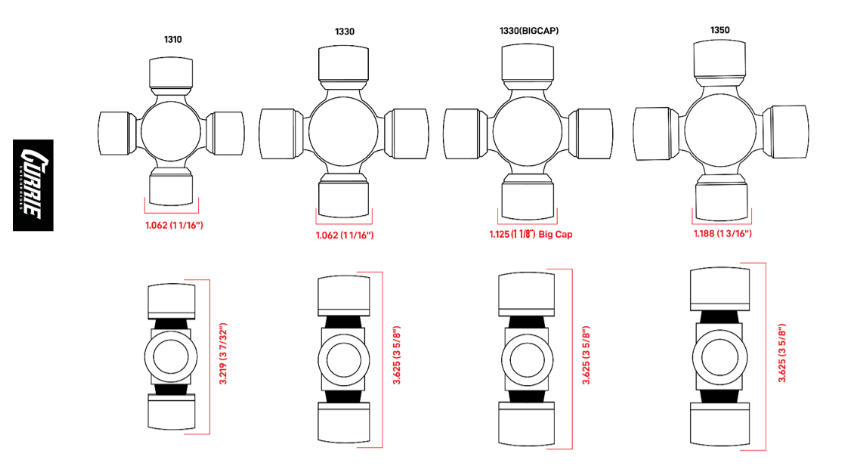

Series & Measurements Of U-joints

When building a custom street rod or muscle car with driveline components from multiple sources, it is not uncommon to encounter u-joints of different sizes. Because your vehicle is now a custom application, going to the local auto parts store and looking up a u-joint by year-make-model won't work. But don't despair; with some simple measurements, it's possible to determine the required u-joints.

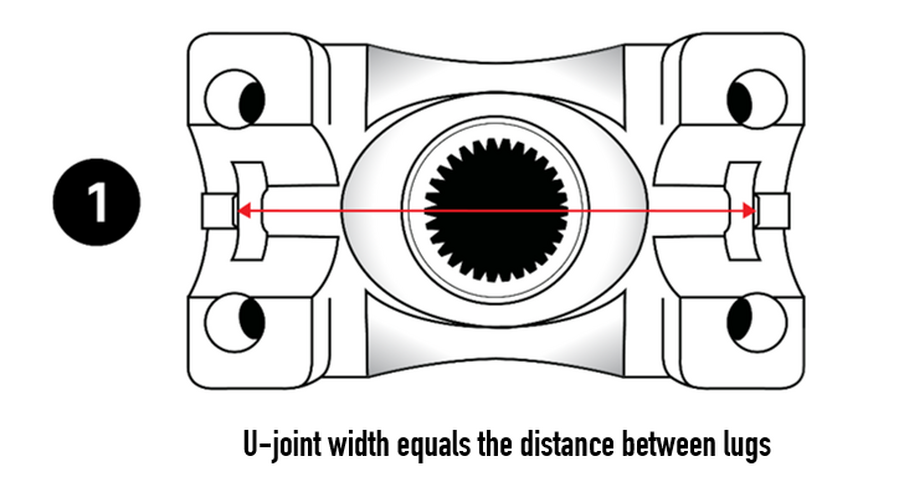

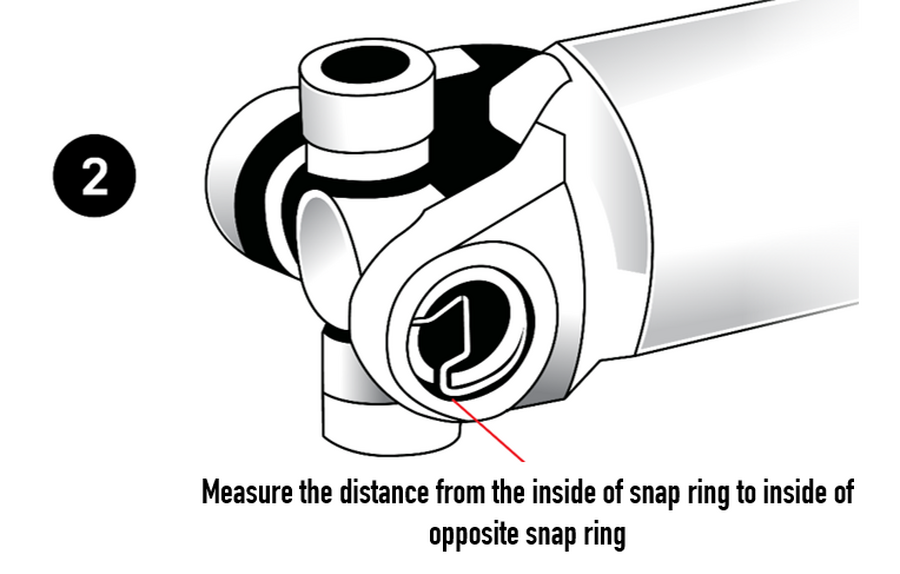

Most common driveshaft u-joints applications will use outside locks, where lugs (image 1) or snap rings (image 2) are used to secure and align the u-joint caps in the yoke.

Determining the u-joint series for external lock applications is a simple matter of measuring a few critical dimensions.

Measuring for Driveshaft U-joint Fitment

If you don't have the u-joint

1: Measure the distance between the lugs of the transmission and pinion yokes and the distance between the snap rings of the driveshaft yoke to attain the overall widths

2: Measure the yoke gap and the diameter at the cap location to get the cap diameters.

Make sure to check all of the width and diameter dimensions, as they may be different. If the dimensions do not match, you may require a conversion u-joint.

If you have the u-joint

1: Measure the outside distance across the u-joint (with caps installed)

2: Measure the diameter of the caps

Make sure to check all of the width and diameter dimensions, as they may be different.

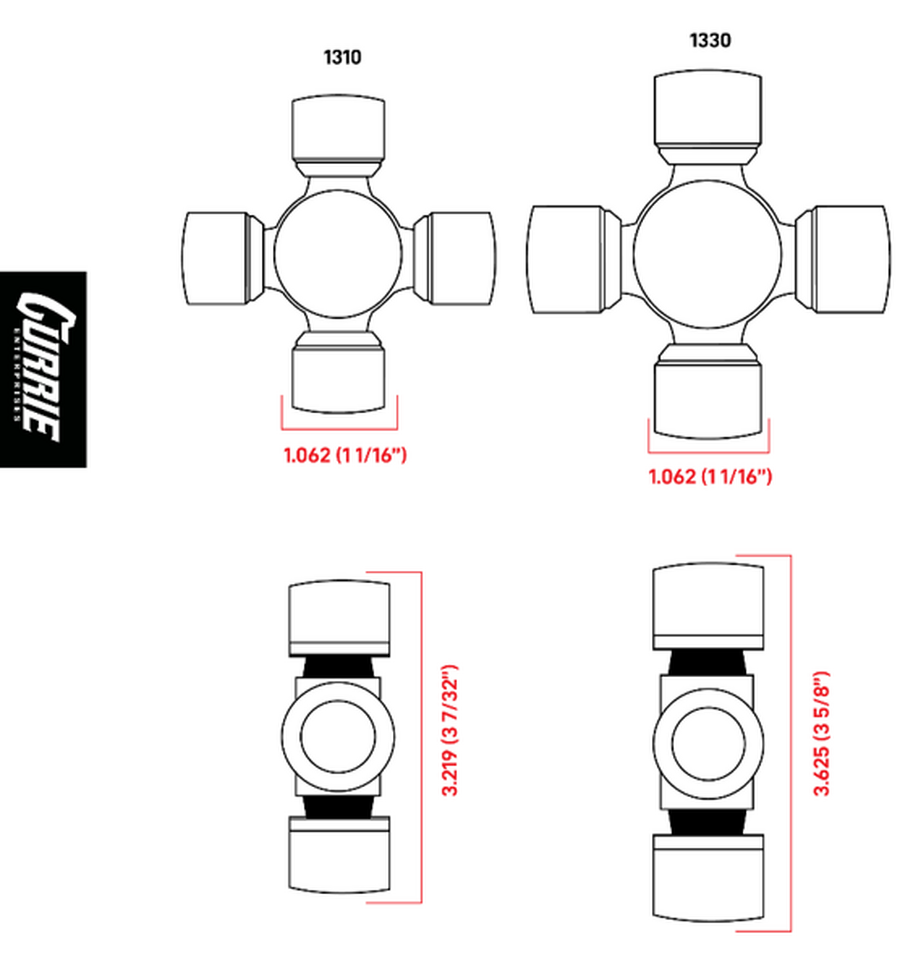

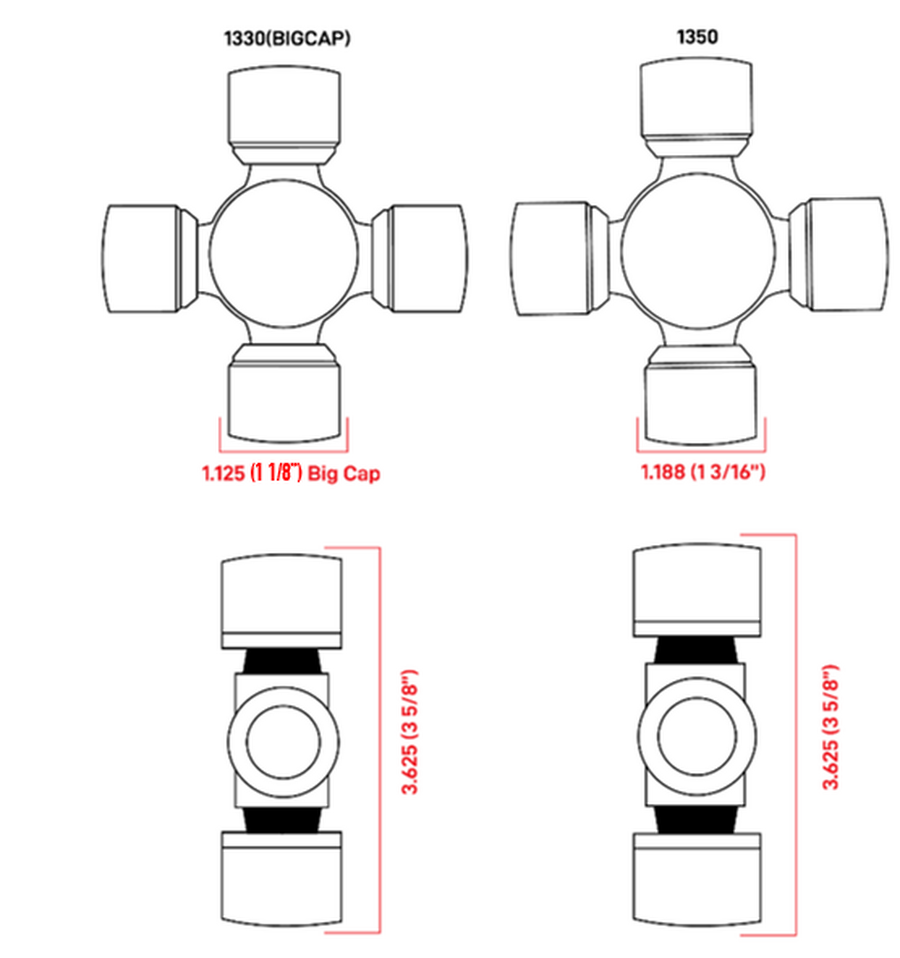

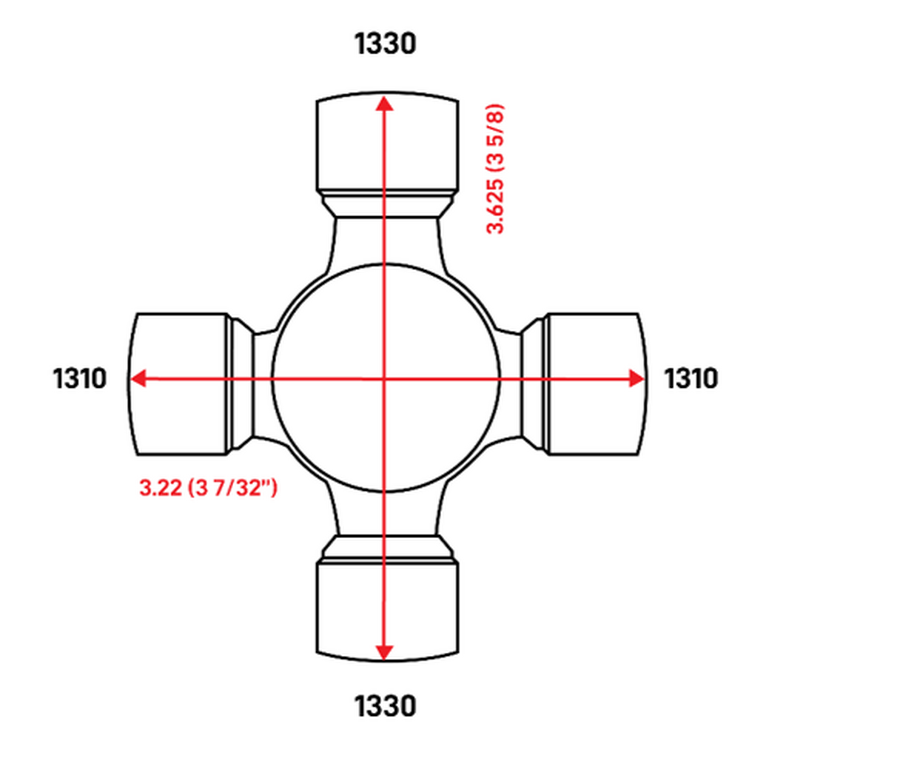

Standard u-joints sizes are classified by series, with each series having specific cap diameter and overall joint width. Typically speaking, a higher series number translates to a stronger joint.

Standard U-joint Series, Dimensions and Part Numbers

|

Series |

Cross Width |

Cap Diameter |

Spicer P/N |

|

1310 |

3.219 (3 7/32”)(81.76mm) |

1.062 (1 1/16”)(26.97mm) |

5-1310X |

|

1310BC* |

3.219 (3 7/32”)(81.76mm) |

2 @1.062 (1 1/16”)(26.97mm) |

5-7439X |

|

1330 |

3.625 (3 5/8”)(92.07mm) |

1.062 (1 1/16”)(26.97mm) |

5-1330X |

|

1330BC* |

3.625 (3 5/8”)(92.07mm) |

2 @ 1.062 (1 1/16”)(26.97mm) |

5-7438X |

|

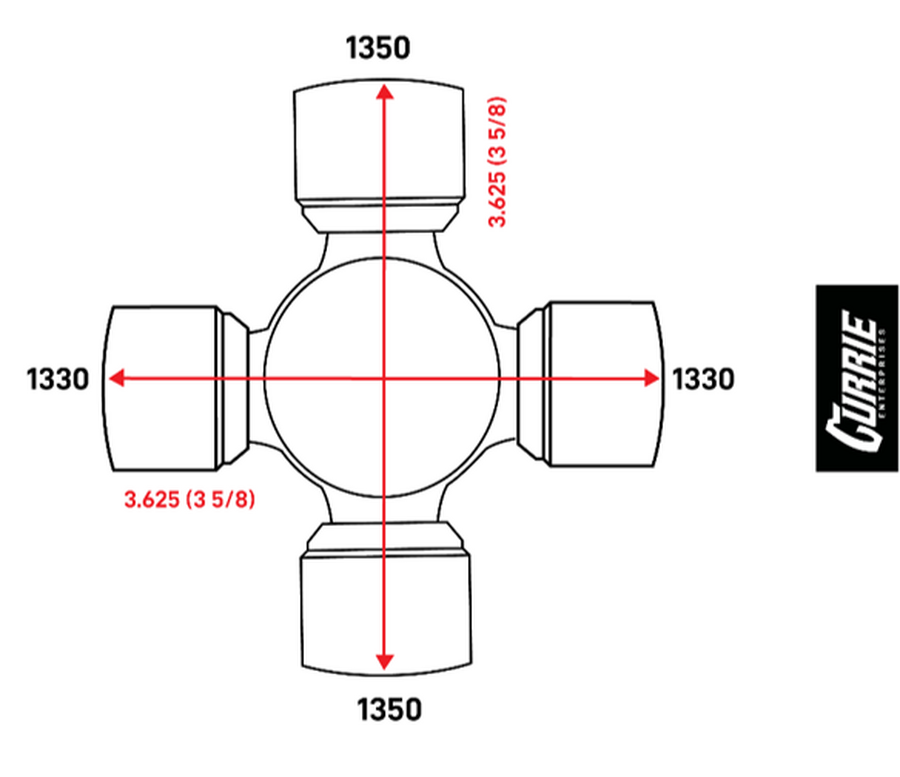

1350 |

3.625 (3 5/8”)(92.07mm) |

1.188 (1 3/16”)(30.17mm) |

5-1350X |

*BC denotes Big Cap, a Ford creation with two thicker caps to resist the deformation caused by over-torquing of the u-bolt straps.

Conversion or combination u-joints

include a mix of two different series specifications in the same joint so that that mismatched yokes and driveshafts can be connected. The caveat is that the joint is only as strong as the smaller series.

Conversion U-Joint Series, Dimensions and Part Numbers

|

Series |

Cross Widths |

Cap Diameter |

P/N |

|

1310/1330 |

3.219 (3 7/32”)(81.76mm) |

1.062 (1 1/16”)(26.97mm) |

Spicer |

|

1310/1330BC* |

3.219 (3 7/32”)(81.76mm) |

2 @ 1.062 (1 1/16”)(26.97mm) |

Neapco |

|

1310/1350 |

3.22 (3 7/32”) |

2 @ 1.062 (1 1/16”)(26.97mm) |

Spicer |

|

1330/1330BC* |

3.625 (3 5/8”)(92.07mm) |

2 @ 1.062 (1 1/16”)(26.97mm) |

Spicer |

|

1330/1350 |

3.625 (3 5/8”)(92.07mm) |

2 @ 1.062 (1 1/16”)(26.97mm) |

Spicer |

|

1330BC*/1350 |

3.625 (3 5/8”)(92.07mm) |

2 @ 1.125 (1 1/8”)(28.57mm) |

Neapco |

*BC denotes Big Cap, a Ford creation with two thicker caps to resist the deformation caused by over-torquing of the u-bolt straps.

Strength Ratings

U-joint strength depends on many factors, including material type, body design, the presence of a zerk fitting, cap size, etc. The chart below summarizes the continuous lifetime operating torque and yield torque values (the point at which the u-joint begins to deform)

U-Joint Series Torque Ratings

|

U-Joint |

Continuous Lifetime |

Yield |

|

1310 |

130 lb-ft |

1,600 lb-ft |

|

1330 |

150 lb-ft |

1,850 lb-ft |

|

1350 |

210 lb-ft |

2,260 lb-ft |

U-Joint Strap Kits

| U-Joint Series |

Width Center/Center |

Torque Specifications |

Currie Strap Kit P/N |

| 1310/1330 | 1.416 in. | 14-17 Ft-Lbs | CE-4058 |

| 1330 BC* | 1.590 in. | 14-17 Ft-Lbs | CE-4059 |

| 1350/1410 | 1.666 in. | 20-24 Ft-Lbs | CE-4060P |

*BC denotes Big Cap, a Ford creation with two thicker caps to resist the deformation caused by over-torquing of the u-bolt straps.

Quoted politely from currieenterprises.com